The IREAD4.0 project aims at developing an integrated system for the monitoring and automatic management of pallets and vehicles, in large warehouses characterized by high rotation index of products (warehouses larger than 10,000 $m^2$ with an average goods handling of more than 1000 items per day). From an optimization point of view, this project includes the resolution of two crucial problems for such warehouses through Operations Research techniques.

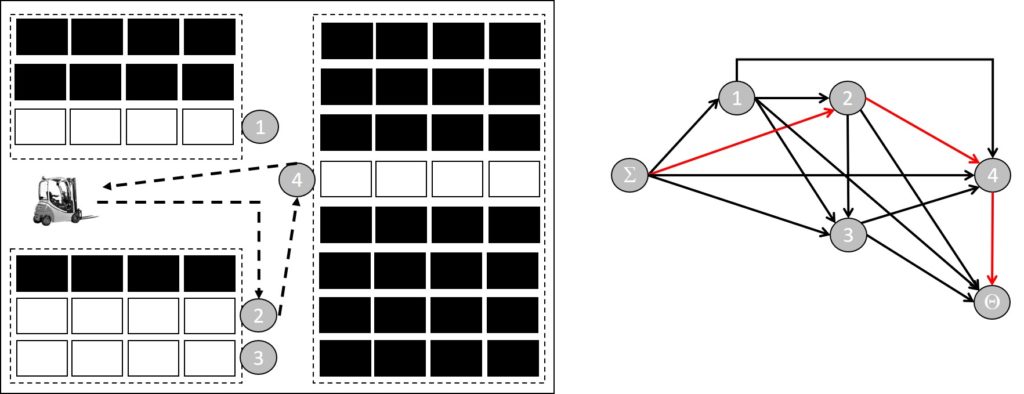

The first problem arises when items of several different product types need to be stored somewhere in the warehouse, and the selection of the most suitable positions for items need to be decided by respecting specified storage policies and product requirements. The second problem arises when items need to be actually moved within the warehouse by vehicles (such as forklifts) to perform storage operations (moving items form the production area towards their assigned storage locations) or retrieval operations (moving items from their storage locations towards the loading docks), once customer orders are set. The sequencing of operations, the scheduling and the paths of vehicles are the decisions to make here.

Both problems are formulated in terms of constrained multicommodity flow problems over suitably structured graphs through mixed integer linear programming models. The dimensions of both problems made necessary the development of specific resolution approaches (matheuristic and heuristic) to quickly find solutions that achieved specific performance requirements.

IREAD4.0 project has been funded by the Region of Tuscany under the programme POR FESR 2014-2020 Bando 1 – Progetti Strategici di ricerca e sviluppo